FAQ

- From which quantities can you order from us?

- Which plate sizes, can you still send with the parcel service?

- How should I mark the direction of the wood grain when placing an order?

- Can you cut plywood also for stencils or templates?

- What is the difference between a rotary- or sliced cut veneer?

- Can you Marine plywood with mahagony rotary cut veneers also produce with other or additional cover veneers?

From which quantities can you order from us?

The smallest surface that you can order is 100x100mm.

Which plate sizes, can you still send with the parcel service?

To enable shipping with a parcel service, the following rules are apply:-The package can not be longer than 2.00 meters.

-The length of the package + the belt circumference (height + width + height + width in meters) must not exceed 3.00 meters.

For example, you would like to order a 10mm thick plywood board, with measuring 2.00 meters in length, then the width

of the plywood board should not be more then 0.45 meters:

2.00 meters long + 0.45 meters wide + 0.01 meters high + 0.45 meters wide + 0.01 meters high = 2.92 meters

(we also need some clearence for the packaging)

of the plywood board should not be more then 0.45 meters:

2.00 meters long + 0.45 meters wide + 0.01 meters high + 0.45 meters wide + 0.01 meters high = 2.92 meters

(we also need some clearence for the packaging)

How should I mark the direction of the wood grain when placing an order?

This is quite simple because: The first measurement is also the specification of the maser progression.Order a board with an measurement indication of e.g. 200x150mm, then the grain runs on the 200mm:

A measurement indication of 150x200mm, takes the grain runs to the 150mm:

Can you cut plywood also for stencils or templates?

Yes, of course, the cutting, for example, trapezoidal surfaces, arcs or curves according to dimension or template is possible.The calculation is based on time expenses.

What is the difference between a rotary- or sliced cut veneer?

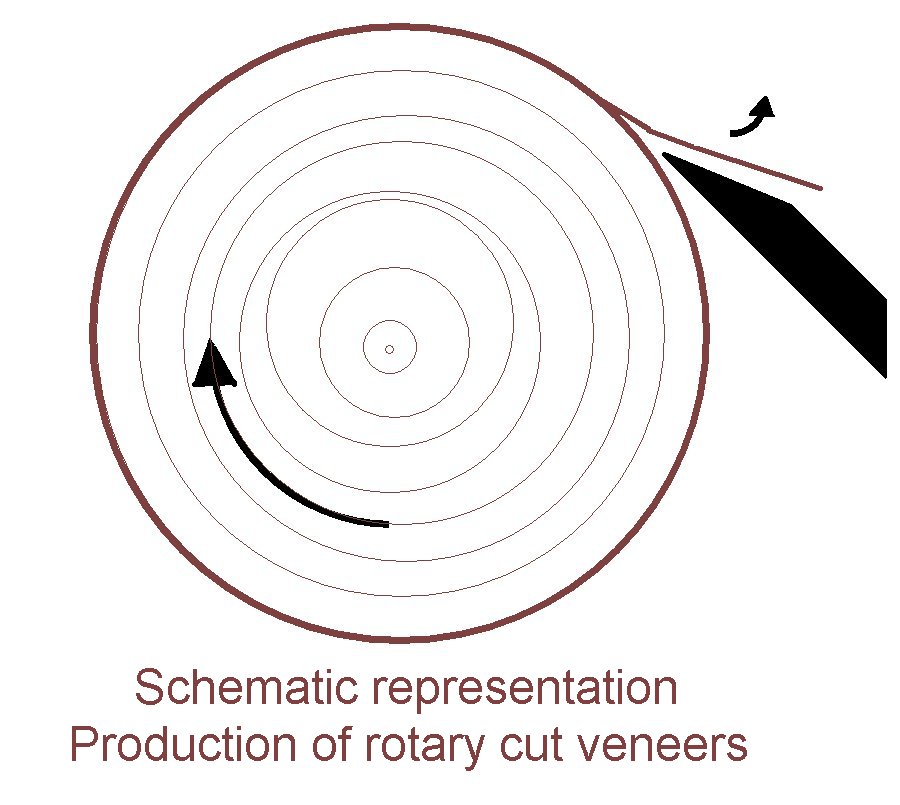

Rotary cut or sliced cut ??actually means only the manufacturing process of veneers. When rotary cutd veneers, the log is clamped at the ends and made to rotate. Laterally, a knife is then set, which then peels the tlog mm for mm downright like an apple. The veneer pictures are then rather blurry. The advantage is that the log can be used almost 100% for the veneer production. Plywood with rotary cut veners results in a cheap sheet material that can be used anywhere where the design only matters and their surfaces are invisible.

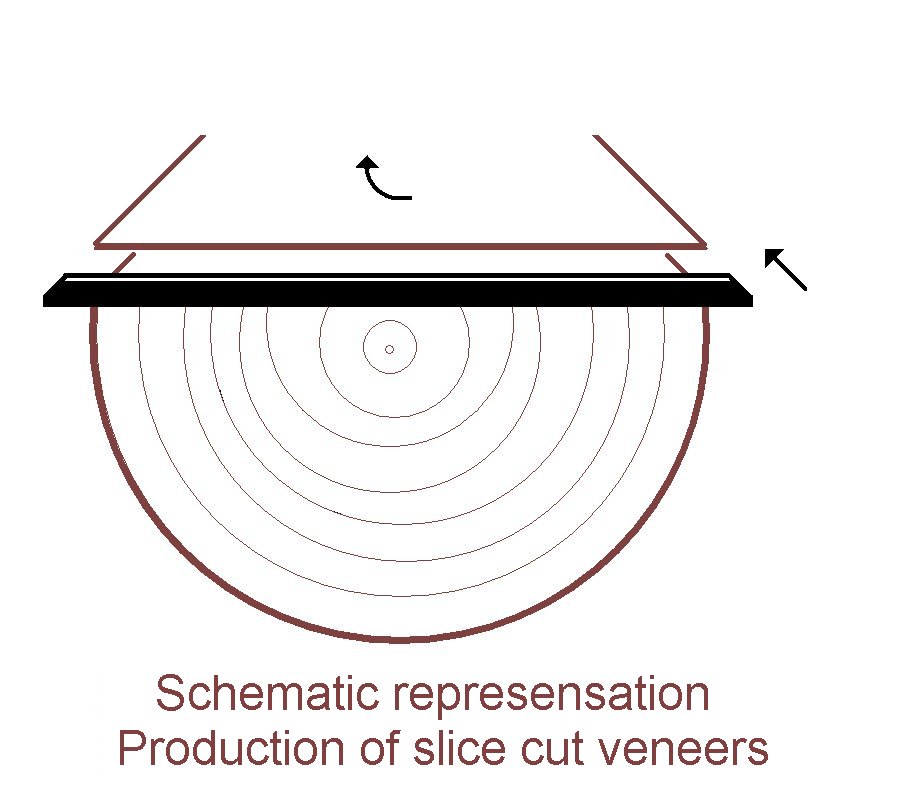

With sliced cut veneers, the log remains rigidly clamped. The knife is then pulled layer by layer across the commpletten trunk. The resulting veneer pictures are finer and more clearly drawn. However, the utilization of the log for the veneer production is far below that of the rotary cut veneer production

Can you Marine plywood with mahagony rotary cut veneers also produce with other or additional cover veneers?

Yes. Depending on availability, the veneering of these boards with wood species such as e.g. beech, oak, cherry etc. possible.The top layers can also be provided with thick veneers (1.50 mm) of mahogany or teak veneer.

The calculation is based on time or material costs. For inquiries please contact us via Info@TischlereiBehn.de